Pergolas are one of the most popular elements of landscape design that allows you to transform the appearance of any site. A variety of products made of wood, metal, polycarbonate and other materials allows owners of country houses to choose a gazebo, which will help create an atmosphere of coziness and comfort. DIY polycarbonate pavilions are the best option for creating a strong, durable and at the same time visually weightless design that will be a decoration of the yard for many years.

Polycarbonate advantages over other materials

It should be borne in mind that you will not lose at all if you use polycarbonate during construction. This material, which is widely used in construction, has a number of properties that advantageously set off it against the background of other transparent building materials.

Due to the special structure of the material, polycarbonate plates do not break during impacts and do not give chips and cracks

The main advantages of cellular polycarbonate include:

- High impact resistance (8 times stronger than acrylic plastic and 200 times stronger than glass).

- Extreme lightness (6 times lighter than acrylic and 16 times lighter than glass). For the installation of lightweight polycarbonate panels, solid support structures are not required.

- The ability to withstand temperature changes from -40 to +120 degrees, as well as snow and wind loads. This feature makes cellular polycarbonate an ideal roofing material for arbors, greenhouses and other light-transmitting structures.

- High heat and noise insulation performance and light transmission with transparency up to 86%. The outer side of the panel is covered with a special layer that protects against ultraviolet radiation.

And also this material is easy to process - bending, drilling, cutting.

In addition, the cost of polycarbonate panels is an order of magnitude lower compared to the same metal, and a wide range of colors allows you to choose the best option, the use of which will ideally fit the design into the site design

Construction stages

Do-it-yourself installation of a polycarbonate gazebo, like any building structure, is carried out according to a certain algorithm.

Step # 1 - choosing and preparing a place for the gazebo

Pavilions are placed near the house, as well as in the recreation area. It’s great if this place is located in the shade of trees and away from drafts.

The choice of a place for the gazebo primarily depends on the functions that the design will perform. When planning to create a capital gazebo of a large area, you should prepare the basis for the construction of the structure. A flat area is suitable for this purpose, the groundwater level of which is located quite low. Having the site in the lowland, the structure should be protected from flooding, and for this a solid foundation should be built for it. Arbors can be installed either directly on the ground, or on a specially erected platform - the base. When deciding to create a gazebo for relaxing and gathering cheerful companies at the table, it will be sufficient to establish only supporting pipes as the basis.

If there is a pond on the site, then it is very reasonable to place the gazebo not far from it so that in the midday heat provide an additional influx of fresh air

The most common forms of arbors: square and rectangular, triangular, round and oval. The design of a traditional square gazebo can be decorated with a single-pitched or gable roof, as well as a tent-type roof

Step # 2 - preparing the foundation

If under the small and light arbors you can not lay a special foundation, then the foundation is required for the construction of capital structures. To do this, make a markup of the territory and designate places for future columns for the frame. Filling the platform under the gazebo can be performed in parallel with the installation of columns. To install the columns, you need to dig holes of a size sufficient to fit inside two bricks. At the same time, there should still be a place for falling asleep 10 cm of the soil layer.

The columns are installed inside the pit, filled with screenings and poured with cement. Cures cement in a few days

The columns are installed inside the pit, filled with screenings and poured with cement. Cures cement in a few days. To prevent moisture from entering the hardening cement in the pit, you can cover the base of the columns with a film.

Step # 3 - frame assembly process

The material of manufacture can be both wooden poles and metal profiles. Wood is an inexpensive and easy-to-use material that requires constant care to extend its life. Metal is a material, durable and resistant to temperature extremes, whose service life is an order of magnitude longer compared to wood.

The principle of assembly of the frame resembles the work with the designer and is quite simple in execution

Elements of a wooden structure are fastened with nails and self-tapping screws, and metal - with screws and nuts. When working with metal, it is desirable to combine the types of joints, using also the welded joint of parts.

Step # 4 - glazing the gazebo with polycarbonate

Polycarbonate can act not only as a material for the arrangement of the roof, but also for fragments of wall coverings. Windows made of polycarbonate for the gazebo will bring additional sunlight to a cozy corner for relaxation and make the construction light. Figured holes in the side covers, carved with a hacksaw, will create a visual effect of weightlessness and openwork.

If you will make a roof of polycarbonate, then it can be fixed using conventional screws. There are also special thermal washers

So, first, the outlines of all the light-transmitting parts of the gazebo are transferred to the prepared polycarbonate sheets. After that, with the help of an electric jigsaw, a hacksaw or a sharpened knife, the parts are cut along the contour. Sufficient ease of cutting sheet is one of the valuable properties of polycarbonate. Drill holes in the polycarbonate parts to connect to the metal structure.

Rubber washers with screws and silicone sealants will prevent unwanted leaks in the structure and destruction of the base of the sheets. To isolate the corner joints and join several parts, it is advisable to use special elements that can be purchased with polycarbonate sheets.

Design and care of the gazebo

A comfortable and beautifully designed gazebo will become a favorite corner in the garden, where you can enjoy birdsong and unity with nature. In addition, for communication with guests, there will now be no need to go into the house, and instead spend time in a pleasant conversation in the fresh air.

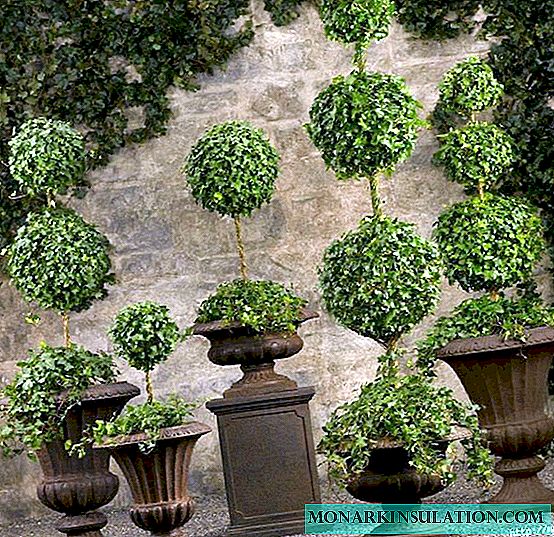

Climbing plants planted along the walls of the gazebo and entwined with a structure will give this corner a special appeal and coziness.

The gazebo made of polycarbonate is able to serve as a functional element of landscape design for a period of at least ten years. The construction does not require special care.

The windows and roof of the gazebo, made of a transparent material that is resistant to temperature extremes, are only periodically washed with water from a hose or wiped from dirt with a damp cloth. Contaminants are easily removed with ordinary soapy water. For cleaning, it is undesirable to use detergents, which include chlorine, alkali, salts and harmful abrasive substances, which can damage the outer layer with ultraviolet protection.

Sheets of brightly colored tones, used instead of traditional transparent sheets, allow you to give the design an original look